The fiberglass is nearing the end of its smoothing process. We applied another layer of filler to it just to make it super smooth.

We sanded the upper cowling half a little bit and exposed all of these pinholes that will need to be filled before we paint it.

Here is the lower cowling duct that guides air from the front of the cowling to the oil cooler near the firewall.

The battery and oil tank were installed on the firewall.

And so was the oil cooler.

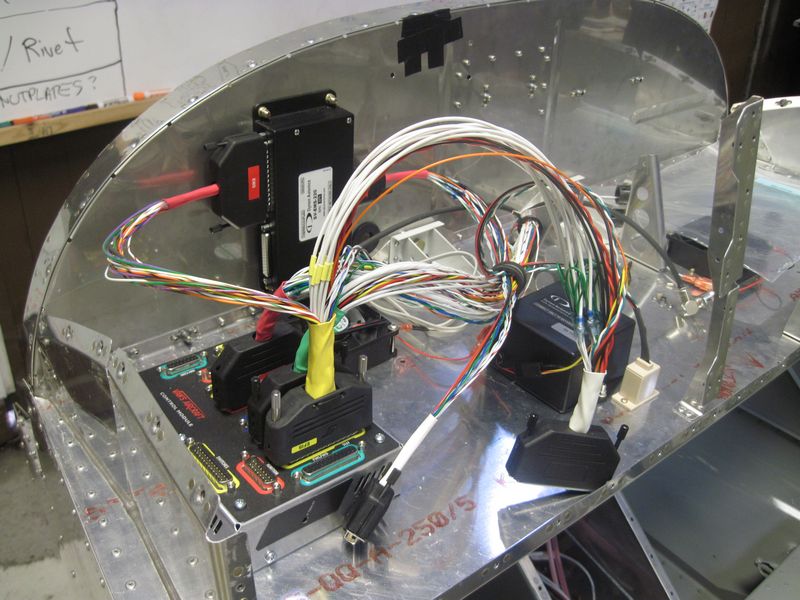

Our avionics started to go together with the installation of the computer module, the EMS (engine monitoring system), and the Dynon backup battery. We have it pretty easy though compared to most homebuilders, for our wires come in prepackaged bundles so we can just plug-n'-play.

More next week!